- SPU: AL-N6RC-7cwsipij[D4]

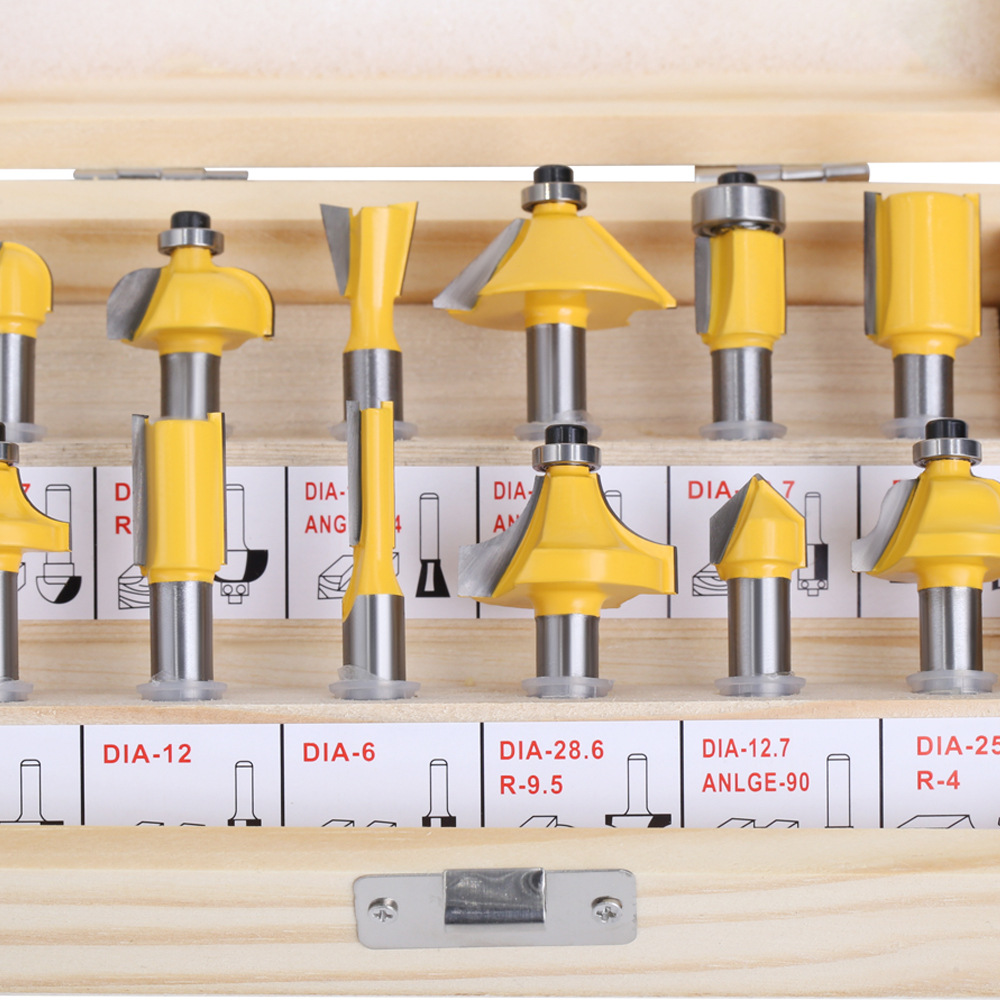

- Model: Blade inner diameter 20, outer diameter 24, thickness 5

- Model: Blade inner diameter 18, outer diameter 22, thickness 5

- Model: Blade inner diameter 16.5, outer diameter 19, thickness 5

- Model: Blade inner diameter 15.5 outer diameter 18 thick 5

- Model: handle

- Model: Inner diameter 15.5, outer diameter 18 blade + handle

- Model: Inner diameter 16.5, outer diameter 19 blade + handle

- Model: Inner diameter 18, outer diameter 22 blade + handle

- Model: Inner diameter 20, outer diameter 24 blade + handle

- Model: Complete set (one handle + 4 blades)

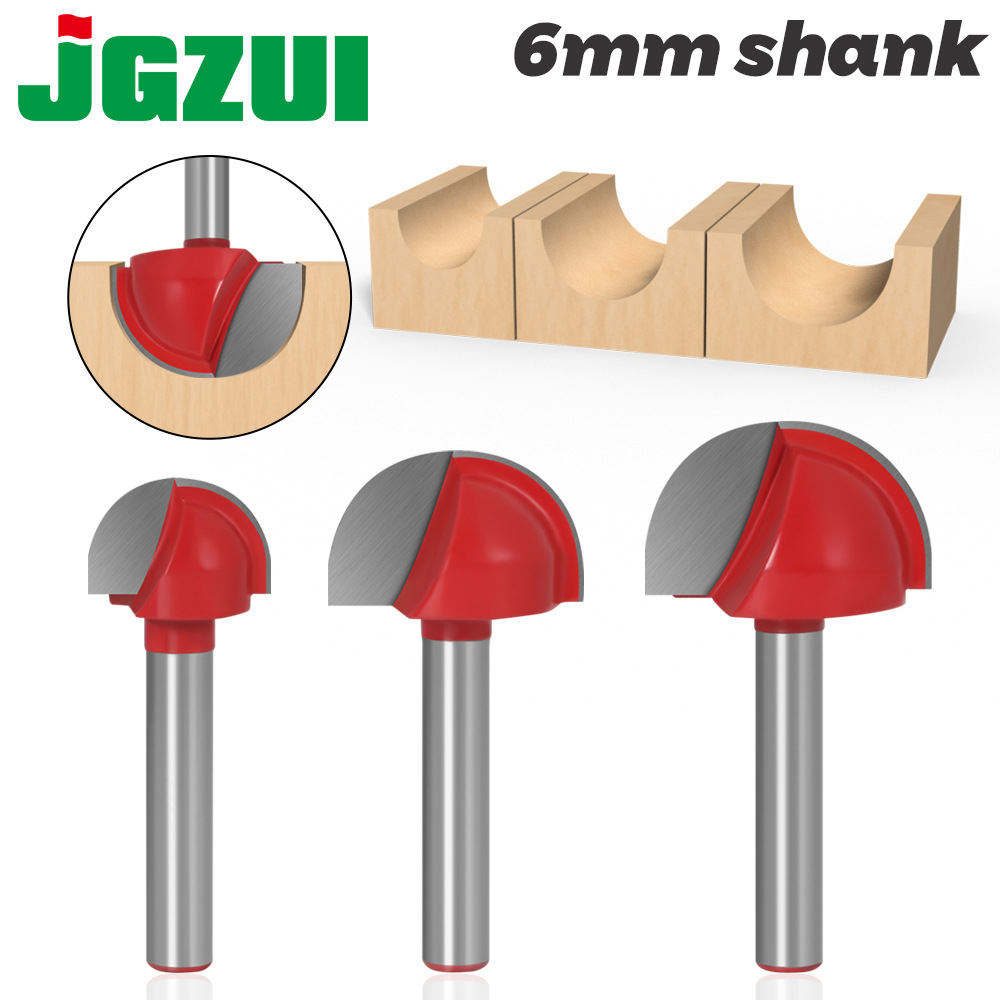

- Ball head diameter (mm): 10

- Chamfer angle:90

- Center minimum cutting diameter (mm): 15.5

- Contour radius (mm):15.5

- Cutting diameter (mm): 24

- Maximum depth of cut: 20

- Number of effective peripheral cutting edges: 2

- Functional length (mm):50

- Helix angle:90

- Handle form: straight handle

- Handle diameter (mm): 10

- Format: Domestic

- Series: Forming Knife

- Cutting edge form: drill

- Material: white steel

- Type: Forming milling cutter

- Number of slots: 2

- Blade length: 20

- Blade diameter: 2

- Shank diameter: 10

- Full length:50

- Whether coated: non-coated

- Applicable machine tools: drilling machine

- Processing scope: wood

- Specifications (diameter*full length): 50

- Maximum cutting diameter (mm): 20

- Product Category: Milling Cutter

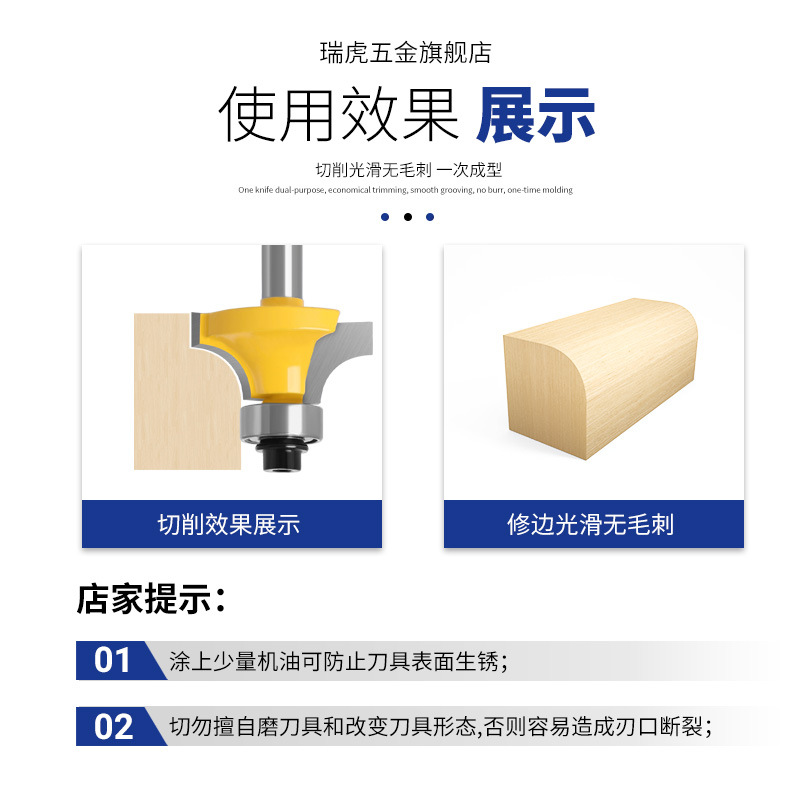

Use technology sharing:

This is how I use it: 1. Before drilling, first center, use a twist drill bit to drill the hole in the wood board to be drilled, and drill through; 2. Install the knife and install it on the bench drill. Start the bench drill and see if the cutter head swings. After confirming, align the drill hole on the wooden board and drill.( Drilling should be steady and advance slowly. It is best to feel that there is no vibration in front of the drill bit.) , after drilling half of the belt, turn the wood over and align the drill hole with the other side.( Repeat the previous operation) , a rough ring came out.; 3. For polishing, I use a hexagonal handle sanding rod with a piece of wood in front that can be inserted into the wrench. Knock the sanding rod in, then put the wrench on, rotate it on the machine, and use sandpaper 400 mesh, 800 mesh, 1500 mesh, 3000 mesh. Just grind with 7000 grit and finally polish with cotton cloth. The inside of the polishing is done with a wrench, so that it becomes a wrench.