- SPU: AL-CN1R-6xskcnuu[2]

- Model: 40 pieces/small box [please take pictures of the whole box for batch size]

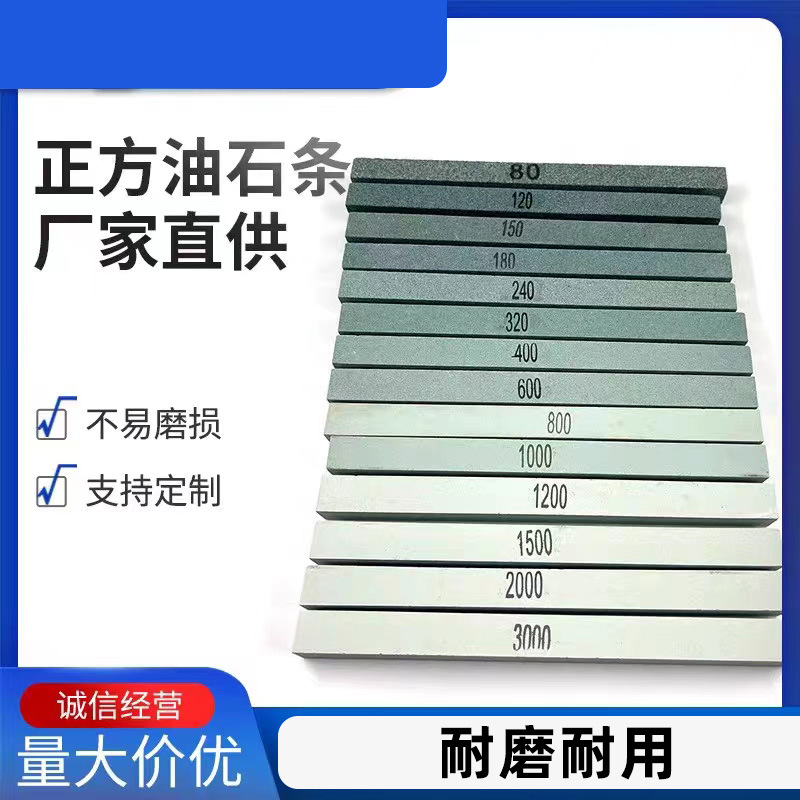

- Shape: Square

- Material: green silicon carbide

- Scope of application: jade, jade, agate

- Processing customization: special processing is available

- Specifications and models: square whetstone 80#

- Specifications and models: square whetstone 120#

- Specifications and models: square whetstone 150#

- Specifications and models: square whetstone 180#

- Specifications and models: square tarstone 240#

- Specifications and models: square whetstone 320#

- Specifications and models: square tarstone 400#

- Specifications and models: Square Whetstone 600#

- Specifications and models: Square Whetstone 800#

- Specifications and models: Square Whetstone 1000#

- Specifications and models: Square Whetstone 1200#

Notice--- Because the grindstone is relatively slender, it may break during transportation even if it is carefully packaged. Damage caused by this reason will not be accepted for return or exchange.! Please read carefully before purchasing. If you do not accept this description, please do not purchase. Thank you.!!!

use: Can be used for grinding and polishing metal, jade, knives, molds!

[ Instructions]:

1. First put the oil stone into water and soak it for about 15 minutes.

2. Grind in one direction with even force, angle 10%-20% .

3. Do not scrape off the slurry after slurrying. The effect of grinding with slurry is unexpected.

4. After polishing, remember to wipe it with a damp cloth or rinse it with water and dry it. Clean the surface of the oilstone with a soft brush and place it in a ventilated place to dry.

5. The polishing process is divided into coarse polishing, medium polishing, fine polishing and fine polishing.! Therefore, polishing should be done from coarse to fine, 80-2000# Grinding and polishing in sequence! Can be appropriately separated according to the hardness of the workpiece 1- 2 granularity numbers!

Polishing requires a lot of perseverance, patience, and carefulness, and it is also a good way to cultivate your body and mind.!

jade polishing: After grinding for the first time with No. 240, grind to find out where there is no roughness, then grind with No. 600 for the second time, then use No. 600 for the second time.- Grind at 1000 for the third time, and then use 1500 and 2000 sand bars to polish. Be sure to pay attention to the degree of force. The first and second steps are rough grinding. It is very important to be careful and careful. You can use a little force to remove the knife marks; Then, the third and fourth steps are to rub gently. Use 2000 oilstone and sandpaper, and rub very gently. Do not use force. If you use too much force, it will easily leave traces of sand strips on the baby.; It's almost done. Polishing is a tiring physical job.: the fifth step: If you want to highlight, use a No. 2000 sand bar to polish it, then use white powder, wait for glazing powder, leather, wool, etc., when polishing, the rotation speed is about 1200 rpm. It is appropriate to polish at a rotation speed of 1200 rpm. If the rotation speed is too fast, it will be easily ablated. On the surface of jade, polishing powder is not easy to adhere to the polishing surface.