- SPU: AL-5F4R-7i391usq[3]

- Processing and customization: Yes

- Type: Manual solder extractor

- Material: aluminum alloy + plastic

- Maximum suction power: 1000

- Temperature adjustment range: 350

- Length:190

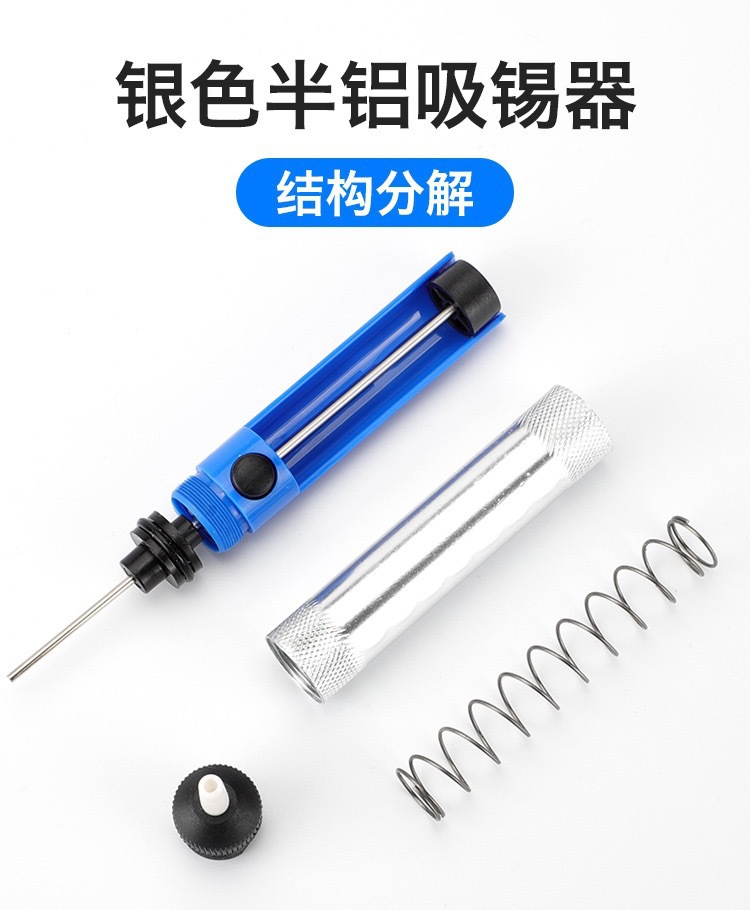

- Specifications: half aluminum

- Scope of application: tin removal

- Number of phases: 1

- Net weight:0.04

- Series:135

|

|

Shenzhen Hanqi Electronics Co., Ltd.

Years of industry experience, factory processing and customization

Customers are welcome to contact us or call us for consultation: 13824499322 Mr. Huang

Customer service online time 9am:00- 18 pm:00

Our store defaults to Yunda Express. If you need to modify the shipping fee, please contact the store customer service.!

Semi-aluminum desoldering pump, small manual powerful desoldering device

Professional auxiliary accessories for welding tools-- One-hand solder extractor, The handle is made of new high-strength materials and aluminum alloy as the shell, high-quality steel as the push rod, and high-temperature resistant polytetrafluoroethylene plastic as the suction nozzle.

Temperature resistant 360°

Powerful suction, simple and easy to use.

color: blue and white/ gold

Material: Half aluminum half plastic

Scope of application: Remove tin

Checklist: 1pc* suction welding pump

size:20* 190mm

Net weight of single item: 34.5g , including card weight: 40g

Number of boxes in inner box100 ,Number of outer cartons:400

net weight/ gross weight:15/ 16kgs

box size meast( cm): 52x33.5x51/ 32x25x23

How to use the solder absorber

1, First, press the solder extractor piston down until it locks.

2, Use a soldering iron to heat the solder joint until the solder melts.

3, While removing the soldering iron, quickly attach the solder suction tip to the solder joint and press the solder suction button.

4, It cannot be cleaned once and can be repeated many times.

Tips for using solder extractor

(1) Make sure the piston of the desoldering device is well sealed. Before turning on the power, plug the small hole in the desoldering device head with your fingers and press the button. If the piston does not pop out easily, it means the seal is good.

(2) The aperture of the desoldering tool head has different sizes, so you need to choose the appropriate specification for use.

(3) After the desoldering tool head is worn out, it should be replaced with a new one in a timely manner.

(4) Before touching the solder joint, dip it in a little rosin each time to improve the fluidity of the solder.

(5) The head should be in contact with the solder joint for a little longer. When the solder melts, draw a circle with your hand clockwise with the solder joint pin as the center, and then press the solder suction button.

|